To get the most out of your ERP project or business transformation, you need to use the right tools. In this podcast, Karl Hiesterman, Senior Manager of Business Process Management at Panorama, explains how to implement business process management in support of your new digital strategy.

Podcast Summary

Let’s Define Some Terminology

- Business Process Management (BPM) – The discipline of looking at how you do things from a process standpoint and using data to make process improvements

- Lean – All about cutting out waste and empowering employees

- Six Sigma – Focuses on removing variation

- Lean Six Sigma – A BPM methodology that helps you evaluate your processes

- Process – A series of logical steps done the same way every time that transforms something into something valuable to the customer

- Customer – Could be the actual customer or the internal customer of a process (anyone affected by a process)

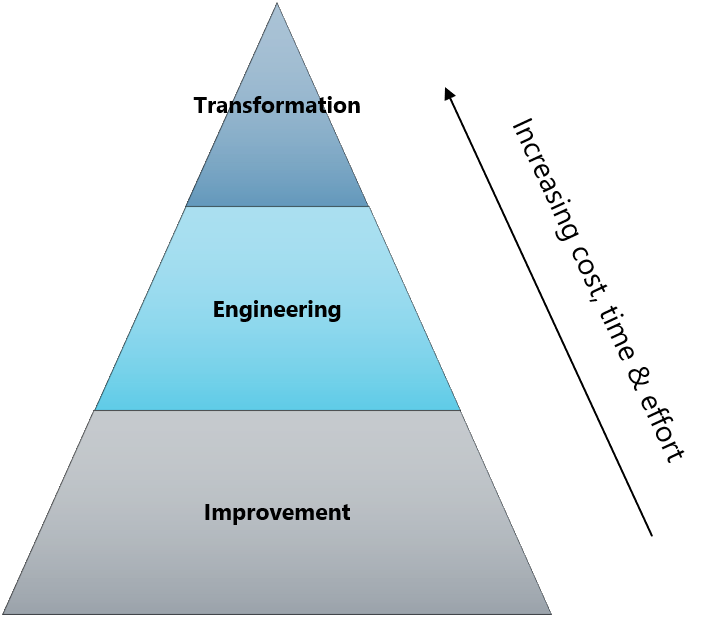

- Business Process Engineering – Starting from scratch and then asking who’s the customer of this process and what are the inputs?

- Business Process Reengineering – Starting with defined processes and understanding pain points, root causes and goals for different stakeholders; then deciding which changes would be most impactful and redesigning relevant processes

- Continuous Improvement – This becomes possible when employees understand a process enough to make small changes overtime

- Digital Transformation – A business initiative often involving customer experience transformation and process engineering.

- Example: Many financial services companies now are looking at themselves as technology companies that provide financial services. This changes the way these companies think and requires them to design new customer-facing processes and applications.

How to Implement Business Process Management in Your ERP Project

While most of our clients are looking for new ERP software, they also have many process issues. This is where we start because ERP implementations are not just about technology. Technology-focused projects put you at risk for automating inefficient processes.

Should You Focus on BPM Before ERP Selection?

In a perfect world, you would continually be improving processes, which would drive your need for new software. However, many companies that come to us haven’t been doing this.

- Risky – Implementing software and doing business process management afterward

- Ideal – Doing business process management early and then selecting software

The reality is somewhere in between. Many companies at least fix the biggest pain points before selection. This ensures that they don’t automate inefficient processes and then are forced to spend money to configure the software when they finally improve their processes.

Prioritizing Process Improvements Using a Payoff Matrix

A key part of knowing how to implement business process management is knowing how to prioritize process improvements.

Once you’ve defined potential process improvements, you should discuss how valuable each one would be on a scale of 1-10. Then, discuss how difficult each one would be on the same scale. With this information, you can create a matrix and divide it into four quadrants to create what is known as a payoff matrix.

In one quadrant, you will find improvements that are very valuable and very easy. We recommend prioritizing these initiatives.

In contrast, you should avoid making the improvements that fall in the “low value and difficult” quadrant. That’s not to say you should never make these improvements. In fact, you may want to revisit them in six months to see if anything has changed in terms of value or difficulty.

Continuous Improvement Deep Dive

We recommend continuous improvement for most organizations. It ensures that you never have to do business process reengineering unless you experience something significant like a merger.

To implement continuous improvement, you should ensure employees are knowledgeable about their processes and empowered to be able to evaluate them. These employees must understand the “why” behind their processes.

If most of your employees don’t have this mindset, you may need a cultural shift. An example of a continuous improvement culture is one where factory employees feel empowered to call attention to any quality problems they spot. Beyond a feeling of empowerment, these employees also understand their processes well enough to know when something seems “off.”

One way to create this culture is to help your team understand who the “customers” of their processes are and what these customers want. To assist in this effort, you can use a SIPOC diagram, which stands for supply, input, process, output and customer. Here, the term “customer” could refer to internal customers (i.e., downstream employees).

When an employee wants to make a process change, they should know that they need to ask these internal customers for approval. This is where process governance comes in. Governance ensures that any changes made align with the entire organization.

Your process governance should be well defined but flexible depending on size of a change. For example, if a change is significant, you may want to require that employees ask for senior management approval.

Customer Expectations & Needs

When improving your business processes, you might find yourself asking the fundamental question, “What is the right level of quality for my organization?”

To answer this question, consider the level of quality your customers need and expect. In most cases, this is the exact level of quality you should aim for – no more, no less.

When it comes to meeting customers’ needs, there are three different approaches a business might take at different points in time:

- Giving customers what they need as opposed to what they expect because they don’t know they need it (i.e., Steve Jobs)

- Keeping up with the competition by making incremental improvements

- Fulfilling customers’ needs and not wasting time making something “super-efficient” if the need is already satisfied

Enjoyed this Podcast?

You can listen to more podcasts by visiting our ERP Podcasts page, and if you’re looking to start an ERP project, you can request a free consultation below to ask our ERP consultants questions about your particular project.